Guidelines For Properly Storing True Cooler Parts

Have you ever wondered how to store True cooler parts correctly to ensure they remain in peak condition? It’s a great question, especially considering how crucial these components are for maintaining optimal temperature control and efficiency. Whether you are a business owner or a maintenance technician, understanding the proper storage of these parts can save you time, money, and effort in the long run.

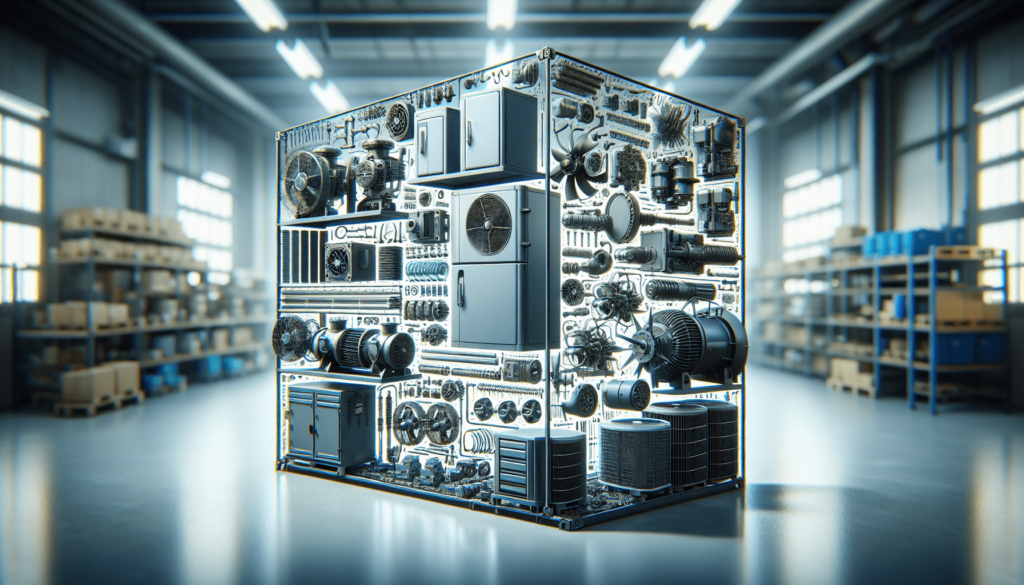

Understanding True Coolers

True coolers are trusted across the food service sector for their reliable refrigeration solutions. They maintain safe temperatures for perishables, which is vital for businesses like restaurants, grocery stores, and catering services. The well-designed components of these coolers work together to provide efficiency and durability, but only if they are cared for properly during storage.

Importance of Proper Storage

Storing True cooler parts the right way minimizes the risk of damage, prolongs their lifespan, and ensures they function properly when reinstalled. By following specific guidelines, you can maintain the quality of these components and avoid costly repairs or replacements.

Preparing for Storage

Before you even think about storing your True cooler parts, a few preparatory steps are essential. This ensures that you start the process on the right foot.

Cleanliness is Key

When components are taken out for storage, it’s vital to clean them thoroughly. Residues from previous usage can lead to corrosion and other types of damage. Here’s how you can do it:

- Disassemble Components: If possible, take apart any sections to clean smaller parts effectively.

- Use Non-Abrasive Cleaners: Opt for gentle cleaners suitable for metal and plastic surfaces.

- Dry Thoroughly: Make sure every part is completely dry before storing; moisture can cause rust and mold.

Organizing Parts

Once clean, organization goes a long way in making your future reassembly smooth. Consider the following strategies to keep everything in order:

| Storage Method | Description |

|---|---|

| Bins | Use clear bins to categorize parts. It helps in easy locating later. |

| Labels | Label each bin or section of storage. Avoid confusion later on. |

| Inventory List | Keep a detailed inventory list of parts stored. Update it as necessary. |

Choosing the Right Storage Environment

Where you store your True cooler parts matters just as much as how you clean and organize them. The right environment helps prevent any potential deterioration.

Temperature Control

Ideally, you want to store parts in a climate-controlled environment. Fluctuating temperatures can lead to the warping of plastic and rubber components. Here are some recommendations:

- Cool and Dry Areas: Aim for a temperature range of 50°F to 75°F.

- Avoid Humidity: Excess moisture can lead to rust and mold.

Light Exposure

Light can be surprisingly damaging to certain materials, especially plastics and rubber. Here’s how to mitigate this risk:

- Store in Dark Spaces: Use opaque storage containers or coverings.

- Avoid Direct Sunlight: Ensure your storage area doesn’t have direct sunlight streaming in.

Proper Techniques for Storage

Knowing how to store each type of component plays a significant role in preventing damage. Whether they are large or small, here’s how to care for them.

Storing Electrical Components

Electrical parts are critical to the operation of your True coolers. Their fragility means special attention is required.

- Use Anti-Static Bags: Store electrical parts in anti-static bags to prevent electrostatic discharge (ESD).

- Keep in Controlled Temperatures: Extreme temperatures can damage circuits; store them where temperatures are consistent.

Storing Mechanical Components

Mechanical parts like fans, compressors, and hinges need extra care, as these are more susceptible to physical damage.

- Wrap in Protective Material: Use bubble wrap or foam padding to prevent scratches and dings.

- Keep Vertical: Store heavier components vertically to avoid crushing lighter items.

Storing Insulation Components

These parts are vital for maintaining the efficiency of your coolers. Protect them as follows:

- Keep Dry: Moisture can degrade insulation. Store in a dry environment.

- Avoid Compression: Store insulation pieces flat rather than piled on top of one another to prevent compressing.

Scheduled Maintenance Checks

Even if your True cooler parts are stored correctly, it’s wise to conduct regular maintenance checks to ensure their condition.

Frequency of Checks

- Every Three Months: A quarterly check can catch any issues before they snowball.

- After Extreme Weather: Following extremely hot or cold weather, checking their condition is advisable.

What to Look For

During these checks, pay attention to the following:

| Check Item | What to Look For |

|---|---|

| Cleanliness | Dust or grime buildup that may need cleaning. |

| Moisture | Signs of moisture or mold, especially in insulation materials. |

| Physical Integrity | Any signs of cracks, bends, or breakage in parts. |

Handling Right Before Reinstallation

When the time comes to reinstall your True cooler parts, how you handle them can affect their performance.

Gentle Handling

- Use Both Hands: When lifting heavier components, always use both hands to avoid dropping.

- Avoid Strain: Don’t try to force parts into place; if difficulty arises, check for obstructions or compare with stored components.

Final Cleaning

Just before reinstallation, it’s a good practice to clean each part one last time:

- Wipe with a Damp Cloth: Remove any dust or grime that may have settled during storage.

- Check Compatibility: Ensure the part is compatible with the specific model of the True cooler you are working on.

When to Replace Parts

Despite your best efforts at storage and care, sometimes it becomes necessary to replace True cooler parts. Here are signs that it might be time to consider replacements:

Wear and Tear

Regular inspection can help you catch signs of wear early on, such as:

- Cracks or Breaks: Visible damage can hinder performance and efficiency.

- Rust or Corrosion: For metal parts, any rust should prompt immediate replacement.

Performance Issues

If you notice degraded performance when reinstalling:

- Temperature Fluctuations: If your cooler isn’t maintaining the right temperature, parts could be failing.

- Increased Energy Consumption: If your energy bills have suddenly increased, it could be due to malfunctioning components.

Conclusion

Storing True cooler parts correctly should not be taken lightly; it contributes significantly to the overall efficiency and longevity of your cooling equipment. By following the outlined guidelines, you can ensure that your components remain in excellent condition, ready to deliver their best performance when needed.

Remember, proper storage entails cleanliness, organization, and control over the storage environment. Additionally, routine maintenance checks and gentle handling during reinstallation will keep your True cooler functioning at its best. So, as you gear up for storage, take a moment to appreciate the role each component plays and treat them with the care they deserve.

Once you’ve established a reliable storage routine, you can focus on what truly matters—serving fresh and delicious food to your customers. Your efforts towards the proper care of True cooler parts will not only save you from unexpected breakdowns but also elevate the efficiency and reliability of your cooling systems!