True Cooler Parts: Common Mistakes To Avoid During Maintenance

Have you ever found yourself frustrated while trying to maintain your True cooler? It can be a bit tricky, especially when it comes to understanding the parts and how to keep everything running smoothly. In this guide, you’ll learn about some common mistakes that people often make during maintenance and how to avoid them.

Understanding True Cooler Parts

True coolers are reliable and high-quality pieces of equipment that require proper maintenance to function optimally. Knowing the parts of your True cooler is essential for effective maintenance. Familiarizing yourself with these components will help you troubleshoot issues and avoid common mistakes during upkeep.

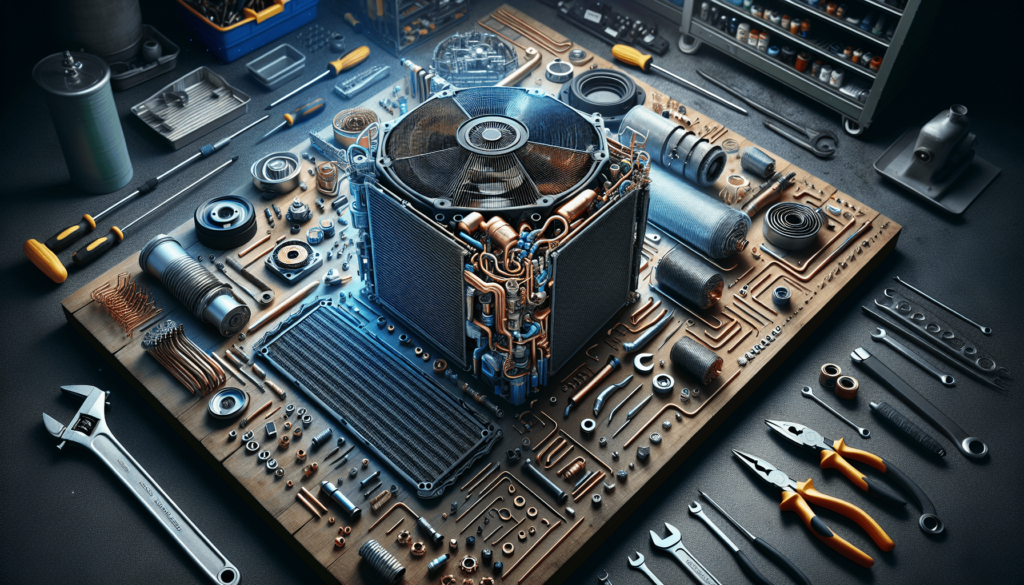

Key Components of a True Cooler

Here’s a quick breakdown of the main parts of a True cooler:

| Component | Description |

|---|---|

| Compressor | The heart of the cooling system, compressing refrigerant gas. |

| Condenser | Responsible for dissipating heat from the refrigerant. |

| Evaporator | Absorbs heat from inside the cooler, allowing the refrigerant to cool the air. |

| Fans | Circulate air throughout the cooler to maintain a consistent temperature. |

| Thermostat | Regulates the temperature inside the cooler. |

| Door Seal | Ensures that cold air stays in and warm air stays out. |

Knowing these components will help you take appropriate measures during maintenance.

Common Mistakes in Maintenance

Even seasoned users can make mistakes while maintaining their True coolers. Being mindful of these common pitfalls will save you time, money, and hassle.

Neglecting Regular Cleaning

One of the most common mistakes is skipping regular cleaning. Dust, dirt, and debris can accumulate in various parts of your cooler, ultimately affecting its performance.

Why It’s Important

Regular cleaning improves airflow and ensures efficient cooling. It also helps to prolong the lifespan of your True cooler.

Best Practices

- Frequency: Aim to clean your cooler at least every three months.

- Supplies: Use mild soap and water for cleaning, and avoid harsh chemicals.

- Focus Areas: Pay attention to the condenser coils, fans, and door seals.

Ignoring Component Checks

Another mistake is overlooking the checks on essential components like the compressor, evaporator, and thermostat.

Understanding Component Failures

Each part plays a vital role; ignoring them can lead to significant issues down the line. A failing thermostat could cause temperature inconsistencies, while a dirty compressor could lead to overheating.

Tips for Checking Components

- Compressor: Listen for unusual noises during operation. If you hear clanking or grinding, it might be time for a professional check-up.

- Evaporator: Inspect for frost buildup. Excessive frost can indicate airflow issues.

- Thermostat: Test it periodically to ensure it’s accurately reading the temperature.

Overlooking the Door Seal

Many people forget about the door seal, yet this small component plays a crucial role in maintaining cooling efficiency.

Importance of a Good Seal

A damaged or dirty door seal can let cold air escape, causing your cooler to work harder and consume more energy.

How to Maintain the Door Seal

- Inspection: Regularly check the integrity of the seal for cracks or gaps.

- Cleaning: Wipe down the seal with a mild cleaner to remove grime.

- Replacement: If the seal is compromised, replace it to enhance efficiency.

Improper Temperature Settings

Setting the wrong temperature can also lead to problems. Many users fail to adjust the thermostat according to seasonal changes or inventory needs.

Ideal Temperature Range

For most beverages and perishable items, the recommended temperature range is between 32°F to 38°F.

Guidelines for Setting the Temperature

- Adjust seasonally: In summer, you may need to set it lower to account for the heat.

- Monitor regularly: Use a thermometer to confirm that the internal temperature matches your settings.

Failure to Address Refrigerant Issues

Another common mistake is neglecting to check the refrigerant levels in your True cooler. Low refrigerant can lead to inefficient cooling and even damage to the compressor.

Signs of Refrigerant Problems

Keep an eye out for these signs:

- Ice buildup on evaporator coils

- Inconsistent temperature readings

- Hissing or bubbling noises

What to Do About It

If you suspect refrigerant issues, it’s best to consult a licensed technician who can safely assess and recharge the system.

Routine Maintenance Checklist

Creating a checklist can make your maintenance routine more efficient. Here’s an example of a simple routine maintenance checklist you can follow:

| Task | Frequency | Notes |

|---|---|---|

| Clean condenser coils | Every three months | Use a vacuum or brush |

| Inspect door seal | Monthly | Replace if cracked or damaged |

| Check temperature settings | Monthly | Adjust as necessary |

| Inspect fans | Every three months | Ensure they are working properly |

| Assess refrigerant levels | Annually | Consult a technician if needed |

| Test thermostat | Monthly | Ensure it’s accurate |

Staying organized with a checklist can help you stay on top of your cooler’s maintenance needs.

The Role of Professional Maintenance

While you can handle many maintenance tasks yourself, there are situations where you should consider professional assistance.

When to Call a Professional

Here are signs you might need a technician:

- Complex electrical issues

- Refrigerant leaks

- Compressor problems

Benefits of Professional Service

- Expertise: Professionals have the necessary training and experience to identify and fix issues quickly.

- Time-saving: Hiring someone can save you time and prevent costly mistakes.

- Warranty safeguards: Proper maintenance by a certified technician can help maintain warranties on parts.

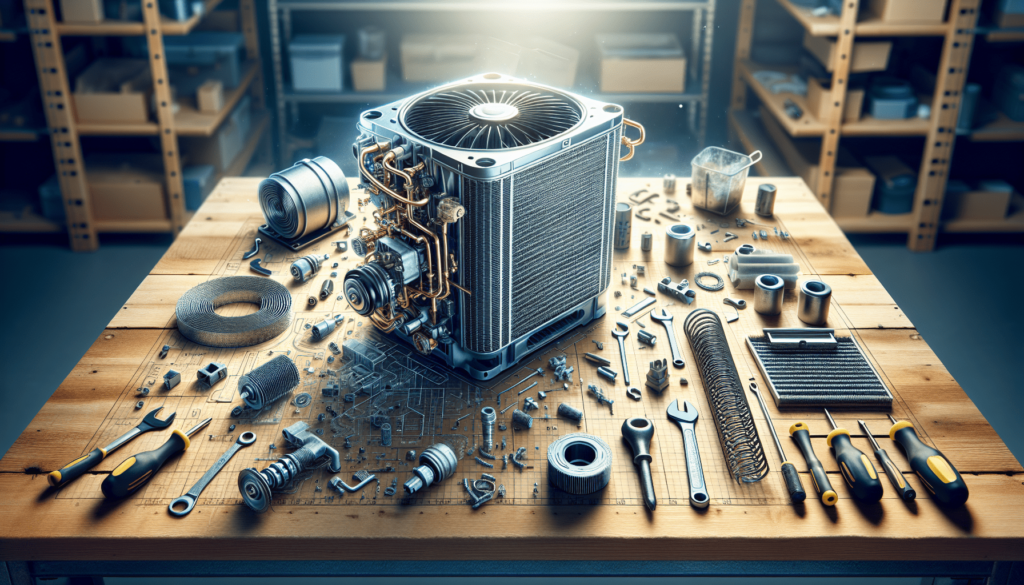

Essential Tools for Maintenance

Having the right tools can make maintenance much easier. Here’s a short list of essential tools you should have on hand:

| Tool | Purpose |

|---|---|

| Screwdriver | For opening panels and removing parts |

| Cleaning brushes | To clean condenser coils and seals |

| Vacuum cleaner | To remove dust and debris |

| Thermometer | To check internal temperatures |

| Multi-meter | For electrical checks |

| Replacement seals | For door seal maintenance |

Keeping these tools accessible will help you tackle maintenance tasks proactively.

Importance of Documentation

Keeping a maintenance log can be incredibly beneficial for tracking the history of your True cooler’s performance and issues.

Benefits of a Maintenance Log

- Traceability: You can easily track when specific maintenance tasks were performed.

- Identify patterns: Noticing recurring problems can help in determining long-term solutions.

What to Include in Your Log

Make sure to document:

- Dates of maintenance tasks

- Observations or issues found

- Parts replaced or repaired

- Professional service visits

Conclusion

Maintaining your True cooler doesn’t have to be an overwhelming task. By being aware of common mistakes and following proper guidelines, you can ensure your cooler remains efficient and reliable for years to come. With the right knowledge, tools, and a bit of organization, you’ll keep your cooler running smoothly and save yourself a lot of headaches in the future. Enjoy having a well-maintained cooler that meets all your needs and stands the test of time!