True Cooler Parts: The Benefits Of Upgrading To Energy-Efficient Options

Have you ever considered how much energy your coolers consume?

Understanding True Coolers

True Coolers are a popular choice for commercial refrigeration due to their reliability and performance. They are often found in restaurants, convenience stores, and supermarkets, ensuring that perishable items are stored at optimal temperatures. However, like any appliance, they can become less efficient over time, prompting the need for upgrades.

The Importance of Energy Efficiency

Energy efficiency is more than just a buzzword; it’s a significant factor for both the environment and your wallet. Upgrading to energy-efficient cooler parts can lead to substantial savings on your energy bills. Moreover, it contributes to reducing your carbon footprint, which is essential in today’s eco-conscious world.

Benefits of Energy-Efficient Upgrades

Transitioning to energy-efficient components for your True Coolers can yield several benefits, including:

1. Reduced Energy Costs

One of the most noticeable impacts of upgrading to energy-efficient parts is the reduction in energy costs. Modern components consume significantly less power than older models. For instance, energy-efficient compressors and fans can offer up to 30% lower energy consumption.

2. Enhanced Performance

Energy-efficient parts tend to operate more effectively. They maintain consistent temperatures, reducing the risk of spoilage and extending the lifespan of your products. This stability is especially crucial for businesses that rely on high-quality refrigeration.

3. Environmental Impact

By opting for energy-efficient solutions, you are also taking a stand for environmental conservation. Lowering energy consumption reduces greenhouse gas emissions associated with electricity production. This not only helps the planet but also aligns your business with current sustainability trends.

4. Improved Equipment Longevity

Using high-quality, energy-efficient parts can enhance the lifespan of your True Coolers. Over time, older components can struggle to maintain efficiency, which can lead to increased wear and tear. Newer, more efficient parts can help alleviate this issue.

Key Components to Upgrade

When considering an upgrade, focus on these key components that can significantly enhance the energy efficiency of your True Coolers:

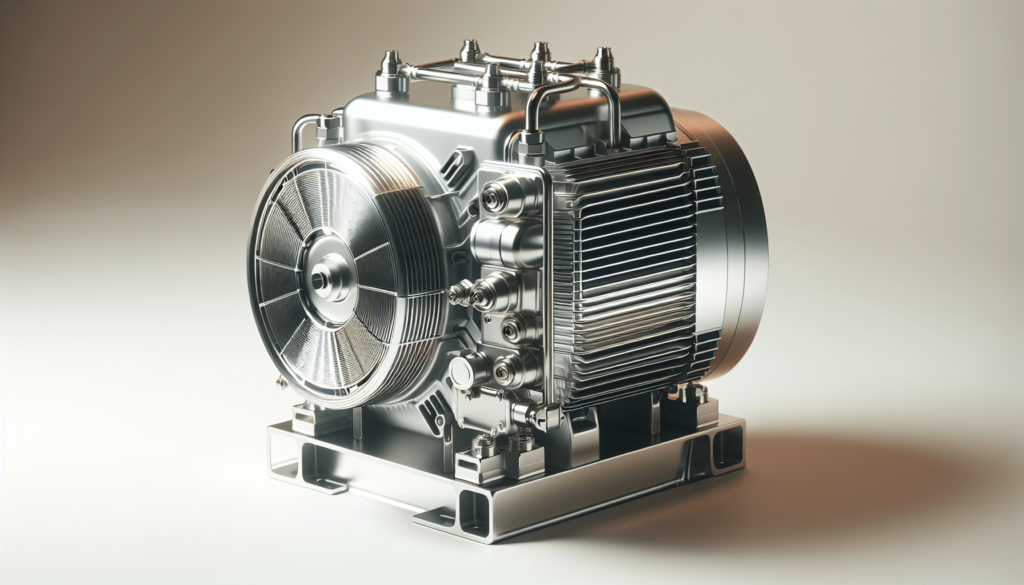

Refrigeration Compressors

The compressor is the heart of any refrigeration system. Upgrading to a modern, energy-efficient compressor can optimize performance while reducing energy use.

- Features to look for:

- Variable speed operation

- Enhanced refrigerant management

- Lower noise levels

Condensers

Condenser coils are responsible for dissipating heat. Upgrading to higher efficiency condenser coils can ensure that the cooler operates at optimal temperature and efficiency.

- Benefits of new condensers:

- Improved heat exchange

- Reduced energy consumption

- Longer lifespan

Evaporators

Efficient evaporator designs enhance the cooling process while minimizing energy consumption. They work in conjunction with the compressor to facilitate the refrigeration cycle effectively.

- Advantages:

- Improved airflow

- Better temperature consistency

- Reduced frost build-up

Insulation

Insulation plays a critical role in maintaining temperatures within a cooler. Upgrading insulation thickness and material can contribute to substantial energy savings.

- Factors to consider:

- Material quality (e.g., polyurethane foam)

- Thickness for optimal thermal resistance

Fans and Motors

Upgrading fans and motors to energy-efficient models can make a notable difference in energy consumption. EC (electronically commutated) motors are an excellent choice for cooler applications.

- Key benefits:

- Reduced energy consumption

- Enhanced airflow efficiency

- Quieter operation

Making the Switch

Now that you understand the benefits of upgrading to energy-efficient parts for your True Coolers, let’s discuss how to make the transition smoothly.

Assess Your Current Set-Up

Before making any upgrades, you should evaluate your current cooler setup. Take stock of the current parts, their conditions, and their energy usage.

Research Compatible Parts

Not all parts are universal, so you need to ensure that the components you choose are compatible with your specific True Cooler model. Consulting the manufacturer’s guidelines and specifications can help you make informed choices.

Budget for Upgrades

While upgrading to energy-efficient parts may have upfront costs, it’s essential to budget for this expense since the long-term savings on energy bills will typically outweigh initial investments.

| Upgrade Area | Estimated Cost | Monthly Savings | Payback Period |

|---|---|---|---|

| Compressor | $1,200 | $60 | 20 months |

| Condenser | $800 | $40 | 20 months |

| Insulation | $500 | $30 | 17 months |

| Fans and Motors | $600 | $25 | 24 months |

Hire a Professional

If you’re not comfortable handling the upgrades yourself, consider hiring a professional technician. They can ensure that the installation is performed correctly, which is vital for the equipment’s efficiency and longevity.

Regular Maintenance and Monitoring

After upgrading, maintaining optimal performance is essential for realizing the full benefits. Regular maintenance helps avoid issues that could lead to inefficiency.

Create a Maintenance Schedule

Draft a maintenance schedule that includes routine checks on compressors, fans, and insulation. Regular inspections can help identify potential problems before they escalate.

Monitor Energy Consumption

Consider installing energy monitoring systems to track energy usage over time. This data will give you insights into your cooler’s performance and highlight areas for further improvement.

The Long-Term Vision

Upgrading your True Coolers to energy-efficient parts is not just a short-term fix; it is an investment in the future.

Increased Profitability

By reducing operating costs through improved efficiency, you can increase your profit margins. The money saved on energy bills can be reinvested into other areas of your business for growth.

Staying Competitive

As sustainability becomes a focal point for consumers and businesses alike, having energy-efficient refrigeration systems can serve as a competitive edge. Many customers prefer to support businesses that are environmentally responsible.

Identifying Energy-Efficient Options

With numerous manufacturers and suppliers available, identifying the right energy-efficient parts for your True Coolers can be daunting. Here’s what to look for:

Energy Star Rating

Look for parts that are Energy Star rated. This label indicates that they meet energy efficiency guidelines set by the EPA, ensuring that they are among the best in energy savings.

Supplier Reputation

Choosing reputable suppliers can ensure that you receive parts that meet quality and performance standards. Research reviews and ask for recommendations from other business owners.

Warranty and Service

Selecting parts that come with a warranty can provide peace of mind. A good warranty reflects the manufacturer’s confidence in their product and can serve as a safety net for unexpected issues.

Conclusion

Making the switch to energy-efficient options for your True Cooler parts is a proactive step that benefits both your business and the environment. By focusing on key components, conducting a thorough assessment, and committing to regular maintenance, you can maximize the advantages of your upgrades.

As you consider making these changes, remember the long-term benefits that come with sustainability, including cost savings and enhanced market competitiveness. Investing in energy efficiency today leads to a brighter, more profitable tomorrow for your business!