The Importance Of Regular True Cooler Parts Maintenance

Have you ever wondered why regular maintenance of your True cooler’s parts is so essential? It’s a question that could save you time, money, and headaches down the road. Proper upkeep not only extends the life of your equipment but also ensures it operates efficiently, leading to less downtime and reduced energy costs. Let’s take a closer look at why regular maintenance should be a priority for anyone relying on True coolers.

Understanding True Coolers

True coolers are renowned for their reliability and efficiency, making them a staple in various commercial settings, from restaurants to grocery stores. They provide optimal refrigeration capabilities to keep your perishables fresh. However, like any essential piece of equipment, they require regular maintenance to function at peak performance.

True coolers are built with several critical components, each playing a role in the overall functionality. When these parts aren’t maintained regularly, they can lead to reduced efficiency, increased operational costs, or even system failures.

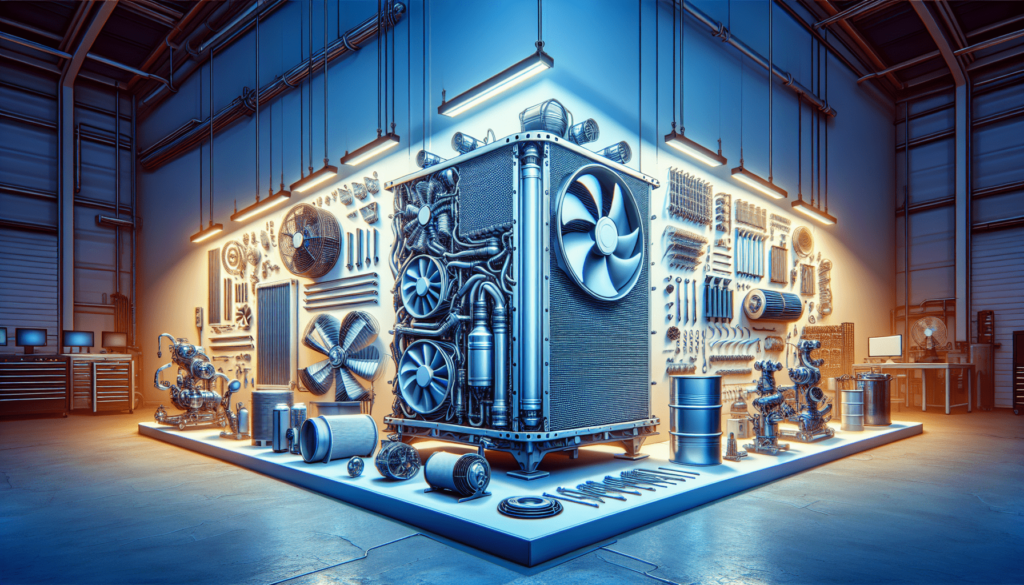

Key Components of True Coolers

To appreciate the importance of maintenance, it helps to understand the primary components of a True cooler and their functions. Below is a simplified breakdown:

| Component | Function |

|---|---|

| Compressor | Pumps refrigerant and helps maintain temperature |

| Condenser Coil | Releases heat and allows the refrigerant to cool down |

| Evaporator Coil | Absorbs heat from inside the cooler to lower the temperature |

| Fan | Circulates air to maintain uniform temperature |

| Thermostat | Regulates temperature settings |

| Door Seals | Prevents cold air from escaping, maintaining efficiency |

Each part has a significant role in keeping your cooler efficient. Thus, regular maintenance ensures that all these components function harmoniously together.

Benefits of Regular Maintenance

When it comes to maintaining True coolers, the benefits extend beyond just avoiding breakdowns. Here are some key advantages to consider:

1. Improved Efficiency

Regular maintenance ensures that the cooler operates at its maximum efficiency. Dust and debris can accumulate over time, affecting airflow and performance. Cleaning filters and coils can improve energy efficiency and reduce operating costs.

2. Extended Lifespan

Taking care of your True cooler not only optimizes performance but also extends its lifespan. Preventative maintenance can catch potential issues before they turn into costly repairs or replacements.

3. Consistent Temperatures

Maintaining consistent temperatures is vital in food storage. Any fluctuation can compromise the quality of your products. Routine checks of the thermostat and cooling components help ensure that temperatures remain stable.

4. Cost Savings

While routine maintenance might seem like an additional expense, it ultimately saves you money. By preventing significant breakdowns and prolonging the lifespan of your cooler, you avoid the high costs associated with emergency repairs or purchasing new equipment.

5. Safety and Compliance

In food service environments, maintaining specific temperature standards is crucial for safety regulations. Regular maintenance helps ensure your cooler meets health and safety codes, reducing the risk of fines or shutdowns.

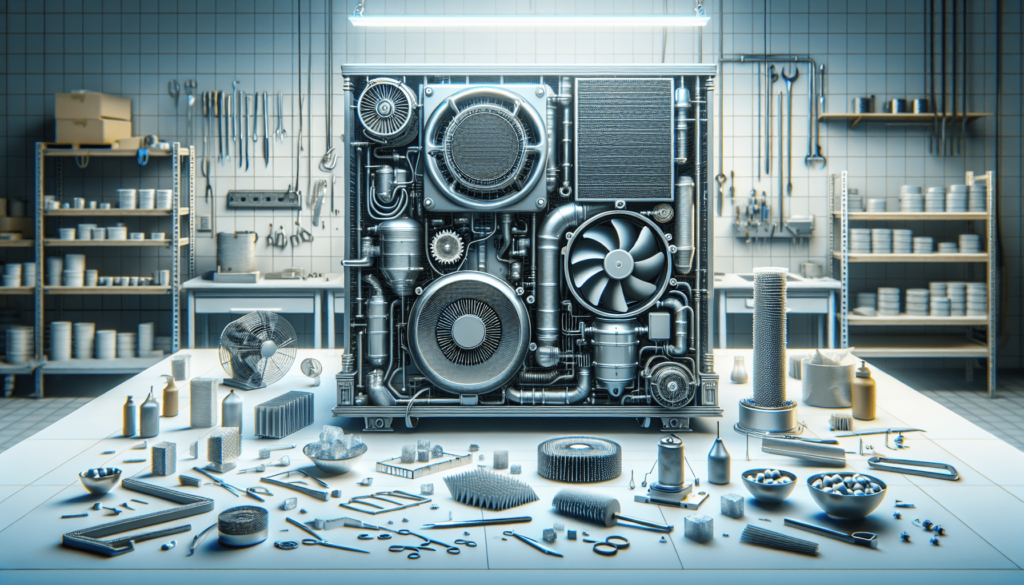

Maintenance Tasks You Should Regularly Perform

Now that you know the benefits let’s discuss the specific maintenance tasks you should routinely perform to keep your True cooler in top condition.

Cleaning the Condenser Coils

The condenser coils are instrumental in releasing heat from the refrigerant. Over time, dirt and dust can accumulate, reducing efficiency. Clean the coils at least every six months, and more often if your cooler is in a dirtier environment.

Checking Door Seals

The door seals ensure that cold air doesn’t escape your cooler. If they wear out or get damaged, it can lead to energy loss and temperature fluctuations. Regularly inspect the gaskets for tears or gaps, and replace them if necessary.

Inspecting the Fan and Evaporator Coil

The fan and evaporator coil work together to circulate cool air. Periodically check the fan blades for dirt and debris and clean them when necessary. Inspect the evaporator coil for frost buildup, which can indicate issues with airflow or refrigerant levels.

Monitoring the Drain Line

A clogged drain line can cause water to accumulate inside the cooler, leading to possible malfunctions. Ensure that the drain line is clear and functioning correctly to prevent leaks and water damage.

Testing the Thermostat

The thermostat controls temperature settings in your cooler. Ensure it’s working accurately by comparing the displayed temperature to an external thermometer. If you notice discrepancies, calibrate or replace the thermostat.

Seasonal Maintenance Checklist

It can be beneficial to have a seasonal maintenance checklist to ensure no tasks are overlooked. Below is an easy-to-follow checklist that you can adapt to your needs.

| Season | Maintenance Task |

|---|---|

| Spring | Clean the condenser coils, check door seals |

| Summer | Inspect refrigerant levels, clean evaporator coils |

| Fall | Test the thermostat and fan functionality |

| Winter | Check and clean the drain line |

Using this checklist will help you ensure that your True cooler operates efficiently throughout the year.

When to Call a Professional

While many maintenance tasks can be handled in-house, some situations warrant a call to a professional technician. Here are a few scenarios where you should consider seeking expert help:

1. Unusual Noises

If your cooler starts making unusual noises, such as grinding or knocking, this could indicate a mechanical issue. A professional can pinpoint the problem before it becomes a significant setback.

2. Temperature Irregularities

If you notice your cooler struggling to maintain the desired temperature, it may require a professional assessment. Issues such as refrigerant leaks might be problematic and should be handled by an expert.

3. Ice Buildup

Excessive ice buildup in the evaporator coils can disrupt airflow and hinder the cooling process. A technician can address this quickly and prevent long-term damage to your cooler.

4. Frequent Repairs

If you find yourself calling for repairs more often, it might be time to consider a full maintenance review by a professional. They can assess your cooler’s condition and recommend a maintenance schedule and necessary repairs.

5. Warranty Protection

If your cooler is still under warranty, certain maintenance tasks might need to be carried out by a certified technician to maintain coverage. Always check your warranty terms.

The Financial Aspect of Maintenance

You might wonder how prioritizing maintenance translates into actual cost savings. Understanding the financial implications can help solidify your commitment to regular upkeep.

Cost of Neglecting Maintenance

Neglecting maintenance can lead to several expenses that outweigh routine care. Some potential costs include:

- Emergency Repairs: Costs can escalate quickly when machinery breaks down and requires same-day or emergency service.

- Energy Bills: Poorly maintained equipment often works harder, leading to substantially higher energy bills.

- Replacement Costs: A cooler that has not been cared for may need replacing sooner than expected, leading to unplanned expenses.

- Loss of Inventory: Equipment failure can lead to spoilage of perishable goods, causing significant financial loss.

Investing in Regular Maintenance

Investing in a regular maintenance schedule can help mitigate these costs. Here’s how:

- Budget-friendly: Routine maintenance and cleaning can be scheduled during slow business hours, making it easier to budget for.

- Predictable Expenses: Regular check-ups make it easier to predict expenses rather than facing large, unexpected bills.

- Lower Utility Costs: An efficient cooler consumes less energy, leading to lower utility bills, which can contribute significantly to your overall operational costs.

In conclusion, investing in regular True cooler parts maintenance is not just a smart move; it’s essential. From saving on repair costs to ensuring the safety and integrity of your stored products, consistent upkeep is valuable in many ways. You will not only prolong the lifespan of your cooler but also create a smoother operational experience for your business. Make it a point to prioritize maintenance—you’ll be glad you did in the long run.