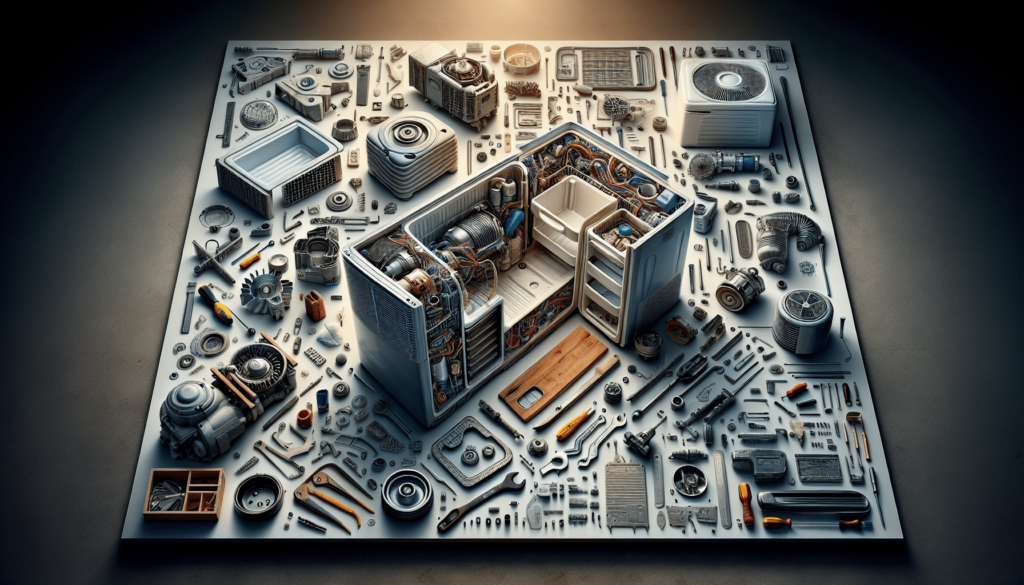

True Cooler Parts: Common Installation Mistakes To Avoid

Have you ever found yourself frustrated while trying to install a cooler part, only to realize that a simple mistake is holding you back? You’re not alone! Even the most experienced technicians occasionally stumble when it comes to proper installation techniques. Let’s take a closer look at some common installation mistakes to avoid when working with True Cooler parts. This guide will help you ensure your installation goes smoothly and correctly.

Understanding True Coolers

True Coolers are renowned for their durability and performance in the commercial refrigeration arena. They are commonly used in restaurants, grocery stores, and various foodservice operations. To keep your True Cooler functioning at its best, it’s essential that every part is installed correctly.

The Importance of Quality Parts

Using genuine True Cooler parts not only enhances the performance and longevity of your unit but also ensures compliance with warranty requirements. When you choose quality parts, you minimize the chances of premature failure or costly repairs. Always opt for the authentic parts designed specifically for your model.

Common Installation Mistakes

Avoiding common pitfalls can save you time and money. Let’s explore the mistakes often made during the installation of True Cooler parts.

Incomplete Assembly

One of the most frequently overlooked aspects of cooler installation is ensuring all components are fully assembled.

- Check for Missing Parts: Before starting, make sure you have all the parts listed in the manual. Missing components can lead to operational failures.

- Follow the Manual: True Cooler manuals provide step-by-step instructions tailored for each model. Skipping steps can result in incomplete assembly.

Incorrect Placement of Components

Each component in a True Cooler is designed to fit in a specific location.

- Misalignment: Make sure each part is aligned correctly. Misalignment can cause leaks or misfunction in cooling.

- Utilize Guides and Slots: Many parts have guides or slots to help you place them correctly. Use these features as they are designed to direct proper placement.

Insufficient Sealing

A common mistake made during installation is not ensuring the seals are intact.

- Use New Gaskets: Always replace gaskets with new ones when installing doors or panels. Old gaskets may not provide a proper seal, leading to energy loss.

- Check for Gaps: After installation, examine the edges of doors and compartments for gaps. A tight seal is essential to maintain internal temperatures.

Ignoring Electrical Connections

Electrical connections are critical for the functionality of True Coolers.

- Securely Fasten Wires: Loose wires can lead to unreliable operations. Check that all connections are secure.

- Be Mindful of Compatibility: Verify that the wiring harness matches your model. Incorrect connections can cause electrical failures or even fires.

Taking Precautionary Measures

To avoid these installation mistakes, consider implementing a few precautionary measures.

Use the Right Tools

Having the proper tools at your disposal can dramatically affect your installation experience.

| Tool | Purpose |

|---|---|

| Screwdriver | For securing screws and fasteners |

| Socket Wrench | For tightening bolts |

| Voltmeter | To check electrical connections |

| Level | To ensure proper alignment |

By using these tools, you can improve the quality of your installation.

Prepare Your Work Area

A cluttered workspace can lead to mistakes.

- Organize Parts: Lay out all parts on a clean surface to ensure you can easily access everything as needed.

- Clear Surroundings: Make sure there’s plenty of room to move around, which reduces the risk of accidental damage.

Double-Check Before Finalizing

Spending a few minutes confirming everything is correct can save you a lot of time later.

- Review Manual Again: Before you wrap up your installation, skim through the manual to ensure you didn’t miss anything.

- Run a Test: Once installed, run a test cycle to monitor functionality. Listen for odd noises, which could indicate a problem.

Frequently Asked Questions

You might have more questions about True Cooler installations. Here are some common inquiries answered.

How do I know if I’ve installed the parts correctly?

After installation, perform a complete functionality test. Check that all components are working as they should and that there are no unusual sounds or issues. Monitoring the internal temperature for discrepancies can also be an indicator of correct installation.

What should I do if I encounter an error code?

Refer to your manual for specific error codes and troubleshooting steps. Often, error codes can be reset, but if issues persist, it may be a sign of improper installation or a defective part.

Can I install parts myself, or should I hire a professional?

If you’re comfortable with basic mechanical tasks and can follow instructions, you may handle some installations. However, if you’re uncertain, hiring a professional is recommended to ensure everything is installed correctly and safely.

Final Thoughts

Avoiding common installation mistakes can significantly affect the performance of your True Cooler. By utilizing genuine parts, double-checking your work, and taking precautionary measures, you can ensure a hassle-free installation process. Remember, taking the time to do it right will go a long way in keeping your cooler running efficiently and reliably.

By following the tips and techniques discussed, you’ll not only enhance the functionality of your cooler but also extend its lifespan. Happy installing!