True Cooler Parts: A Beginner’s Guide

Have you ever found yourself needing to repair or replace parts for your True cooler but weren’t sure where to start?

Introduction to True Coolers

True coolers are a staple in many commercial kitchens and food service environments. Renowned for their durability and performance, these units play a crucial role in preserving perishable goods and maintaining optimal temperatures for both food safety and quality. Understanding the parts of your True cooler is essential for proper maintenance and troubleshooting.

Importance of Knowing Your Cooling System

Having a solid grasp of the components that make up your cooler can help you extend its lifespan and improve energy efficiency. Moreover, when you know the parts, you can make informed decisions about repairs and replacements, which can save you time and money in the long run.

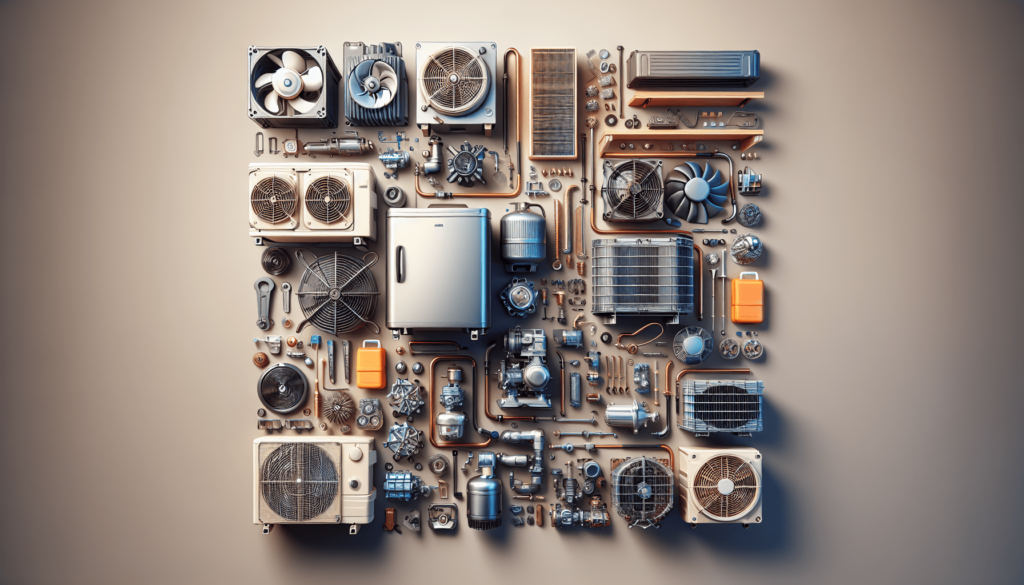

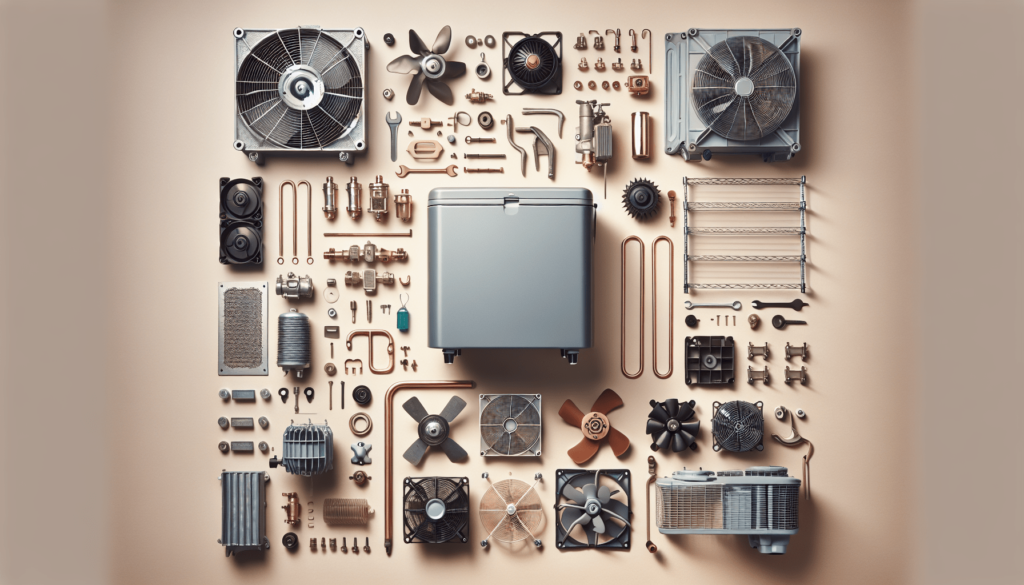

Overview of True Cooler Parts

True coolers consist of several key components, each designed to fulfill a specific function. Here’s an overview of the primary parts you’ll encounter.

Compressors

The compressor is often considered the heart of your True cooler. It compresses refrigerant gas and circulates it through the system to facilitate cooling.

- Functionality: Compressors use mechanical energy to increase refrigerant pressure and temperature, enabling it to release heat efficiently.

- Signs of Failure: Unusual noises, warm air blowing from vents, and frequent cycling are common indicators that your compressor may need attention.

Condensers

Condensers are crucial for dissipating heat collected from the interior of the cooler. They work in tandem with compressors to ensure efficient cooling.

- Functionality: The refrigerant gas released by the compressor moves to the condenser, where it cools and condenses into a liquid.

- Maintenance Tips: Regular cleaning is essential to keep the condenser coils free from dust and debris, allowing for efficient heat exchange.

Evaporators

The evaporator is where the actual cooling occurs, as it absorbs heat from the interior of the cooler.

- Functionality: The refrigerant evaporates in the evaporator coils, absorbing heat and thereby lowering the temperature inside the cooler.

- Common Issues: Frost buildup or improper airflow often indicates that there could be a problem with the evaporator.

Expansion Valves

Expansion valves regulate the flow of refrigerant into the evaporator unit, ensuring that the system operates efficiently.

- Functionality: By controlling the refrigerant flow, the expansion valve helps maintain optimal pressure and temperature for effective cooling.

- Symptoms of Failure: If your cooler is freezing up or not cooling properly, the expansion valve may be malfunctioning.

Fans

Fans are integral for circulating air within the cooler and around the coils, enhancing the cooling efficiency.

- Functionality: They help distribute cool air evenly throughout the cooler and assist in the heat exchange process.

- Maintenance Suggestions: Listen for unusual noises and check for airflow restrictions, which can impede performance.

Thermostats

Thermostats play a crucial role in maintaining the desired temperature inside your True cooler.

- Functionality: They monitor the temperature and signal the compressor to turn on or off as needed to maintain consistent cooling.

- Troubleshooting Tips: If your cooler is running too hot or too cold, check if the thermostat is functioning correctly.

Door Seals

Door seals are essential for maintaining temperature stability within your cooler.

- Functionality: They provide an airtight seal to prevent cold air from escaping and warm air from entering.

- Maintenance Tips: Inspect the seals for damage or wear, and replace them if you notice any gaps or breaks.

Lighting

Proper lighting is vital for visibility inside the cooler, ensuring that staff can easily see and access products.

- Functionality: The lights illuminate the interior, helping with organization and efficiency.

- Upkeep Tips: Regularly check for burned-out bulbs and replace them to ensure optimal lighting conditions.

Common Issues and Solutions

Facing problems with your True cooler is not uncommon. Identifying issues early on can save you from costly repairs later. Here are some common concerns and their solutions.

Temperature Fluctuations

If your cooler isn’t maintaining the correct temperature, it can compromise the quality of stored products.

- Potential Causes: Check the thermostat settings, fan operation, and if the condenser coils are clean.

- Solutions: Adjust settings or initiate a cleaning of components as needed. Consulting a technician may also be beneficial.

Unusual Noises

Noises such as rattling or humming can indicate a problem, especially if they’re louder than normal.

- Potential Causes: Loose components, failing fans, or malfunctioning compressors could be at fault.

- Solutions: Inspect parts visually and tighten any loose screws or fasteners. If issues persist, engage a technician for assistance.

Frost Build-Up

Frost build-up can significantly affect cooling efficiency and should be addressed promptly.

- Potential Causes: Airflow restrictions, defective door seals, or issues with the evaporator could contribute to frost accumulation.

- Solutions: Ensure the airflow isn’t obstructed, check door seals for gaps, and consider defrosting the system.

Water Leaks

Water leaks from your cooler can not only cause damage to the unit but can also pose safety hazards.

- Potential Causes: Clogged drains, damaged seals, or issues with the condensate pump are common culprits.

- Solutions: Clear any clogs from the drain, check seals, and inspect the pump for proper functionality.

Maintenance Tips for True Coolers

Maintaining your True cooler is key to ensuring long-lasting performance. Here are some preventive measures you should consider implementing.

Regular Cleaning

Regular cleaning of your cooler’s interior and exterior surfaces is essential for maintaining hygiene and performance.

- What to Clean: Pay special attention to condenser coils, evaporator coils, and door seals. Use non-abrasive cleaners for best results.

- Frequency: Aim to clean these components at least once every three months, and more frequently if located in dusty environments.

Temperature Checks

Consistently monitoring the temperature can help detect potential issues early on.

- How to Monitor: Use an accurate thermometer to regularly check and log interior temperatures, adjusting settings as necessary.

- Recommended Range: For most commercial coolers, a temperature range of 32°F to 40°F (0°C to 4°C) is ideal for storing perishable goods.

Professional Inspections

Scheduling professional inspections once or twice a year can help pinpoint issues that you might overlook.

- What Happens During an Inspection: A qualified technician can examine refrigerant levels, check for leaks, and ensure all components are operating properly.

- Benefits: Regular professional check-ups can help prevent significant problems and extend the life of your cooler.

Monitor Door Seal Integrity

Keeping an eye on door seals is vital for maintaining efficiency.

- What to Look For: Inspect for wear, gaps, or any physical damage that prevents the seals from closing properly.

- How to Maintain: Clean the seals with warm soapy water and replace them if damaged.

Energy Efficiency Practices

Adopting energy-efficient practices not only saves on costs but also reduces environmental impact.

- Tips for Efficiency: Keep the cooler door closed as much as possible, avoid overloading the unit, and invest in LED lighting to minimize energy consumption.

- Benefits: Implementing these small changes can lead to significant savings and prolonged appliance life.

Repair vs. Replacement: Making a Decision

Undoubtedly, there will come a time when you’ll need to consider whether to repair your True cooler or replace it altogether.

Assessing the Cost

Start by evaluating repair costs versus replacement costs. A good rule of thumb is to consider if the repair is 50% or more of the cost of a new unit.

- Factors to Consider: Cost of parts, labor, and any previous expenses. The age and condition of the cooler should also factor into your decision.

Age of the Unit

If your cooler is several years old, it may be more cost-effective to invest in a new unit rather than sink money into repairs.

- Longevity Considerations: Most True coolers have a lifespan of about 10 to 15 years with proper maintenance.

- Evaluation: Assess how often repairs have been necessary in the past few years. Increased frequency may signal it’s time for a replacement.

Performance Issues

If your cooler experiences ongoing performance issues despite repairs, considering a new unit is wise.

- Analysis: Regular inefficiencies can signify it’s not operating at peak performance, which makes it more costly to run over time.

- Replacement Perks: New units often come with better energy efficiency and updated technology, which can translate to additional savings.

Conclusion

Being familiar with True cooler parts and their functions can empower you to maintain and repair your unit effectively. With a proactive approach to maintenance, you can keep your cooler running smoothly and extend its lifespan. Whether you choose to tackle minor repairs yourself or consult a professional, understanding your cooler’s components will help you make informed decisions.

When it comes to ensuring the quality of the food and beverages you store or serve, every detail matters. Regular attention to these units not only supports your operational integrity but also boosts overall customer satisfaction.