How Often Should You Replace True Cooler Parts?

Have you ever wondered how often you should replace parts in your True cooler? Keeping your cooler in top shape is essential for maintaining freshness and ensuring efficiency. Understanding the right timing for replacement can help you save on costs and avoid unexpected breakdowns.

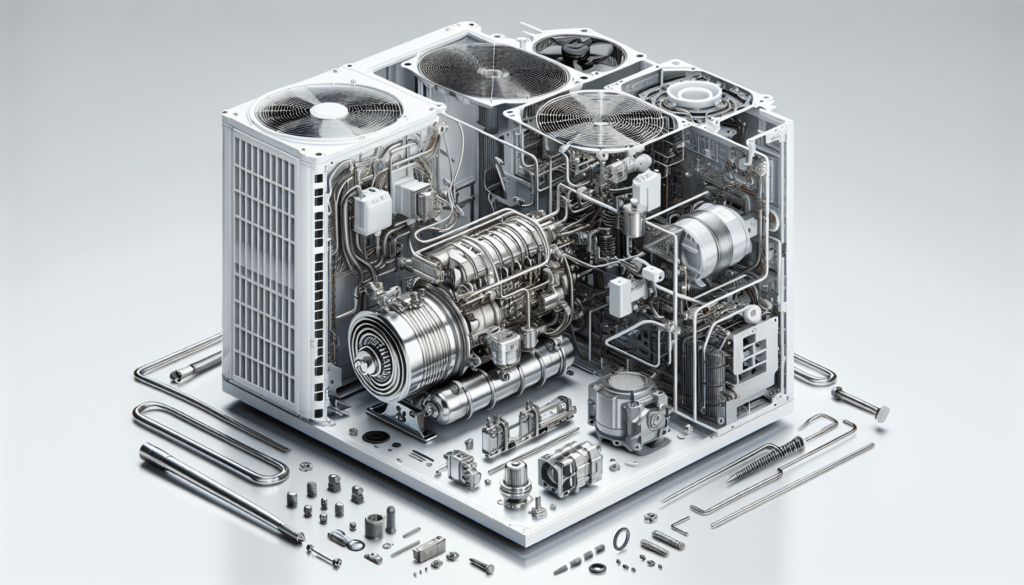

Understanding Your True Cooler

True coolers are popular in the foodservice and retail industries, known for their reliability and efficiency in maintaining optimal food temperatures. These coolers use advanced technology to keep products fresh, but like any appliance, they require maintenance and occasional parts replacement to operate at their best.

Importance of Regular Maintenance

Regular maintenance not only extends the life of your True cooler but also ensures that your business operates smoothly without interruptions. Small issues, if left unaddressed, can lead to more significant problems down the line, which could result in higher repair costs and potential loss of product.

Common Parts That May Need Replacement

To keep your True cooler running efficiently, it’s good to be aware of some parts that are prone to wear and tear. Below is a breakdown of the common parts you may need to replace and how often:

| Part | Replacement Frequency | Signs of Wear |

|---|---|---|

| Compressor | Every 5-10 years | Inconsistent temperatures; unusual noises |

| Fan Motors | Every 3-5 years | Strange sounds; insufficient airflow |

| Condenser Coils | Every 1-3 years | Frost buildup; reduced cooling efficiency |

| Door Seals | Every 2-5 years | Visible damage or wear; drafts felt around the door |

| Thermostat | Every 5-7 years | Inaccurate temperature readings |

| Defrost Heater | Every 5-7 years | Frequent ice buildup; longer defrost cycles |

Compressor

The compressor is the heart of your True cooler. It’s crucial for the refrigeration process. Replacing a compressor can be costly, so it’s beneficial to monitor its performance regularly. If you notice fluctuations in the temperature or hear strange noises, it may be time to consider a replacement.

Fan Motors

Fan motors are vital for circulating air within the cooler. If your cooler is not cooling efficiently, it could be due to a failing fan motor. Keep an ear out for unusual sounds, as these can indicate that the motor needs attention or replacement.

Condenser Coils

Dirty or damaged condenser coils can lead to overheating and reduced efficiency. Regular cleaning is essential, and while you may not need to replace coils often, it’s wise to check them regularly. If you see icing or excessive dust, cleaning or replacement could be necessary.

Door Seals

Door seals are essential to maintain the internal temperature by preventing cold air from escaping. Over time, wear and tear can make these seals less effective, leading to increased energy costs and temperature fluctuations. Checking the seals for any visible damage can prevent bigger issues later.

Thermostat

Your thermostat regulates the temperature inside the cooler. If you find that the temperature readings are inconsistent or incorrect, you might need to replace it. A malfunctioning thermostat can cause your cooler to work harder than necessary, leading to higher energy bills.

Defrost Heater

Defrost heaters help prevent the formation of frost and ice within your cooler. If you notice excessive ice buildup, the defrost heater may not be functioning adequately. Keeping an eye on defrost cycles can help determine if a replacement is necessary.

Factors Influencing Replacement Frequency

Several factors can influence how often you should replace parts in your True cooler. Understanding these can help you make more informed decisions regarding maintenance and replacement.

Usage Intensity

If your cooler is used heavily—such as in a high-volume restaurant—parts may wear out more quickly compared to those in a less demanding environment. Keeping track of usage patterns can provide insight into when replacements may be needed.

Environmental Conditions

The environment where your cooler operates plays a vital role in its lifespan. High humidity, dust, and temperature fluctuations can impact the efficiency and longevity of parts. Ensuring that your cooler is in a suitable environment can mitigate wear and tear.

Routine Maintenance Practices

Establishing a routine maintenance schedule is critical. Regular inspections, cleaning, and servicing can help identify problems before they escalate, potentially extending the life of many components. Skipping maintenance tasks can lead to premature failure of parts.

Quality of Parts

Using high-quality replacement parts can influence the longevity and performance of your cooler. While it may be tempting to opt for cheaper alternatives, investing in quality components often pays off in the long run with fewer replacements needed.

Signs It’s Time for a Replacement

Being proactive about recognizing signs that indicate the need for replacement can save you time and money. Here are the warning signs you should watch for:

Temperature Fluctuations

If you notice that your cooler’s internal temperature is inconsistent, it may be a sign that the compressor or thermostat needs replacement. Ensuring that your products are stored at the correct temperature is vital for food safety.

Odd Noises

Unusual sounds coming from your cooler can indicate problems. Grinding, squeaking, or rattling noises often suggest that parts like the fan motor or compressor are beginning to fail. Addressing these issues early can prevent more significant repair costs.

High Energy Bills

If you’ve noticed a spike in your energy bills, it could be due to inefficient parts. A failing compressor or dirty condenser coils can cause your cooler to work harder to maintain temperature, leading to increased energy consumption.

Visible Damage

Regularly inspect your cooler for any visible wear and tear, especially on door seals and condenser coils. Waiting too long to replace damaged components can result in further issues, including temperature inconsistencies and energy loss.

Frequent Repairs

If you find yourself consistently calling for repairs, it might be a sign that certain parts need replacement. Particularly if multiple issues arise in quick succession, investing in new components could ultimately be more cost-effective.

Benefits of Timely Replacement

Understanding the benefits of timely parts replacement can motivate you to stay on top of your maintenance. Here’s how regular replacement can positively impact your operation:

Improved Efficiency

Replacing worn parts ensures that your cooler operates efficiently. This can lead to better temperature control, reducing the risk of spoilage and saving you money on electric bills.

Extended Equipment Lifespan

Timely replacement of parts can extend the overall lifespan of your cooler. By replacing worn components before they fail, you can avoid a complete breakdown, giving you more time to plan for future expenses.

Enhanced Product Quality

Consistent, optimal temperature control means that your products will maintain their quality. This is particularly important in the food and beverage industry, where freshness is a top priority.

Peace of Mind

Knowing that your cooler is in excellent working condition allows you to focus on other areas of your business. You’ll have peace of mind, knowing you’ve proactively taken care of potential issues before they escalate.

Maintenance Tips for True Coolers

Keeping your True cooler in great shape doesn’t just rely on knowing when to replace parts. Regular maintenance practices are equally essential. Here are some tips to help you maintain your cooler:

Regular Cleaning

Make it a habit to clean the condenser coils every month or as needed. This helps prevent overheating and maintains performance. Pay attention to the interior as well; a clean interior not only looks good but also ensures products stay fresh.

Inspect Door Seals

Check door seals for any visible damage or wear regularly. If you notice any gaps or cracks, consider replacing them promptly to maintain cooling efficiency and lower energy costs.

Monitor Temperature Regularly

Keep an eye on the internal temperature with a thermometer. This can help you catch irregularities early, informing you when components like the thermostat may need repair or replacement.

Schedule Professional Servicing

Consider scheduling professional service at least once a year to conduct thorough checks and maintenance. The technicians can identify problems you might overlook and ensure everything is running optimally.

Keep Vents Clear

Make sure that air vents are free from obstructions. Blocked vents can restrict airflow, leading to increased temperatures and strain on your cooler’s components.

Conclusion

Understanding when and how often to replace parts in your True cooler is essential for maintaining efficiency, product quality, and longevity. Regular inspections and proactive replacements can save you time, money, and perhaps even spoilage disasters down the line.

By paying close attention to components like the compressor, fan motors, and door seals, you can ensure your cooler remains a reliable ally in your operation. Ultimately, a well-maintained True cooler not only protects your investments but also enhances the customer experience by ensuring your products are always fresh and ready to serve.

So, the next time you think about your cooler’s performance, take a moment to evaluate its parts. Remember, staying ahead of maintenance and replacements can pay off dramatically in the long run.