True Cooler Parts: Importance Of Regular Inspections

Have you ever considered why regular inspections of your True cooler parts are so essential? You may rely on your cooler to keep your beverages, perishables, or products at optimal temperatures, but have you thought about how keeping up with maintenance can extend its life and efficiency?

Understanding True Coolers

True coolers are highly regarded in the industry for their durability and effectiveness. They are used in various settings, including restaurants, bars, and grocery stores. What makes them stand out is not just their capacity to maintain cold temperatures but also their construction and design, ensuring optimal performance.

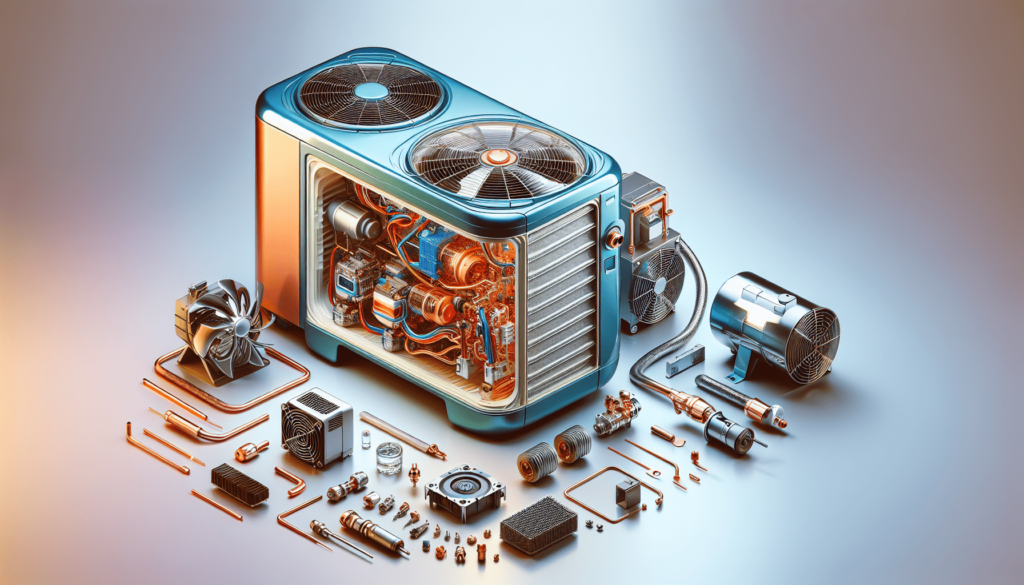

The Anatomy of a True Cooler

To appreciate the significance of regular inspections, it helps to know the main components of your True cooler. The critical parts of a True cooler include:

- Compressor: This is the heart of the cooling system, using refrigerant to create a cooling effect.

- Condensing Unit: Responsible for converting the refrigerant from a gas back into a liquid, it plays a vital role in the cooling cycle.

- Evaporator: Here, the liquid refrigerant absorbs heat from inside the cooler, resulting in a drop in temperature.

- Thermostat: This component regulates the temperature, ensuring it remains at the set point.

- Insulation: Proper insulation reduces energy consumption and keeps the cold air contained.

Knowing these components helps you understand where potential issues might arise and why regular checks are necessary.

The Importance of Regular Inspections

Now that you understand what makes up your True cooler, why are regular inspections so critical?

Prevents Costly Repairs

Regular inspections can identify issues before they escalate into costly repairs. For example, a small refrigerant leak may seem minor, but if left unaddressed, it could lead to compressor failure—something that is much more expensive to fix.

Increases Energy Efficiency

Your cooler works hard to maintain the perfect temperature, and inefficiency can lead to higher energy bills. An inspection allows you to spot issues that could be causing your more energy than necessary.

Extends the Lifespan of Your Cooler

The life expectancy of a True cooler can be significantly extended with regular maintenance. When you catch potential problems early and ensure all components function correctly, your cooler will serve you well for years.

Maintains Optimal Performance

Nobody wants their cooler to fail, especially during peak business hours. Regular inspections ensure your cooler is always performing at its best, helping you avoid awkward situations with customers.

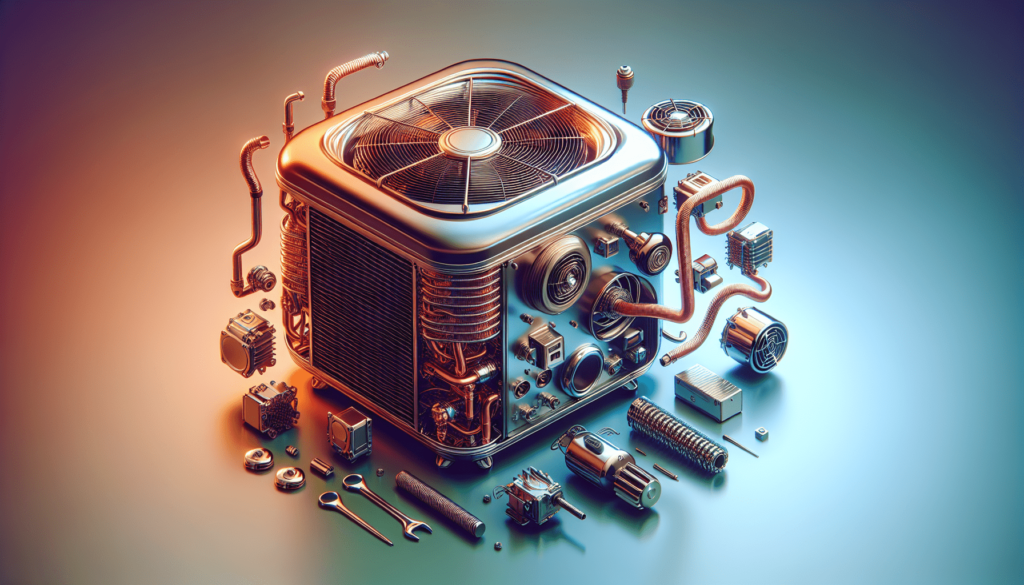

What to Inspect During Maintenance

When conducting routine inspections, there are several key areas to focus on.

Compressor Check

Since the compressor is crucial for cooling, check for any unusual noises or vibrations. Listen for any signs that it may be struggling, as catching this early can save you a lot of trouble.

Electrical Components Inspection

Electrical issues can cause significant problems, including a complete failure of the cooler. Inspect cords, switches, and connections for any signs of wear or damage to ensure everything works correctly.

Cleaning the Condenser Coils

Dust and debris can accumulate on the condenser coils, significantly affecting energy efficiency. Make it a habit to clean these coils regularly so the cooling process can function optimally.

Thermostat Calibration

A malfunctioning thermostat can lead to temperature fluctuations that compromise the quality of the items stored in your cooler. Regularly checking and calibrating it ensures precision in temperature control.

Door Seals Audit

Proper door seals are vital for maintaining internal temperatures. Inspect seals for cracks and wear, as they can lead to energy loss and efficiency issues.

Drain Line Maintenance

Clogged drain lines can lead to condensation issues and promote mold growth. Regularly checking and clearing these lines will help maintain a healthier environment inside your cooler.

Creating an Inspection Schedule

To ensure that your cooler stays in top shape, developing a regular inspection schedule is essential.

Daily Checks

Perform a brief daily check on your cooler. This includes verifying the temperature settings, inspecting the exterior for any damage, and ensuring that the cooler is functioning as it should.

Weekly Maintenance

Set aside time each week for a more in-depth inspection. This should include cleaning the exterior, checking the door seals, and reviewing the condensate drain for clogs.

Monthly Inspections

Every month, conduct a thorough check of the internal components, including the compressor, electrical wiring, and fans. Look for any signs of wear or damage and address them accordingly.

Annual Professional Inspections

While you can handle routine checks, professionals are best for in-depth inspections. Schedule an annual service where a trained technician can examine every detail and provide insights based on expertise.

Signs Your Cooler Needs Attention

Despite regular inspections, you may notice signs that indicate your cooler isn’t functioning as it should. Here are a few red flags to watch for:

Inconsistent Temperatures

If you notice fluctuations in temperature, it might be time to investigate. This inconsistency can negatively impact the items you store and might show a malfunctioning component.

Excessive Condensation

If condensation builds up inside the cooler, this may indicate an issue with the door seals or a problem with humidity control. Sometimes, it’s a simple fix, but it’s important to assess it quickly.

Unusual Noises

Strange sounds like grinding, banging, or hissing can signify internal problems. If your cooler starts emitting noises outside its normal operation, it could be a sign your compressor or fan is struggling.

Increased Energy Bills

A sudden spike in your energy bill without any changes in usage may indicate that your cooler is working overtime due to inefficiencies. Regular inspections can help to identify and remedy this issue.

Frequent Repairs

If you find yourself constantly needing repairs on your cooler, that could be a sign that it’s time for a thorough inspection. An underlying issue could be at play, resulting in multiple smaller repairs turning into larger problems.

Understanding the Costs of Neglect

While it may seem easier to skip inspections or maintenance, the costs can add up if you don’t stay proactive.

Unexpected Breakdown Costs

A cooler breaking down unexpectedly can lead to lost inventory and potential loss of customers. A single malfunction can ruin perishable goods and create customer dissatisfaction.

Higher Utility Bills

Ignoring efficiency means increased operation costs. You benefit from periodic checks by catching issues that can save you money in the long run.

Decreased Equipment Lifespan

Lack of maintenance directly correlates to a shorter lifespan for your cooler, resulting in a more frequent need for replacement.

Reputation Damage

Especially in business, a broken cooler can lead to customer complaints and negative reviews. A positive reputation is built on reliability, so maintaining your equipment is crucial for sustaining that image.

Choosing the Right Parts for Your Cooler

If inspections indicate that you need to replace parts, ensuring you choose the right replacements is very important.

OEM vs. Aftermarket Parts

You have two primary options when it comes to replacing cooler parts: OEM (Original Equipment Manufacturer) and aftermarket parts.

-

OEM Parts: They are more likely to offer reliable performance and durability since they are specifically designed for your model. Although they might be pricier, the investment can result in better long-term performance.

-

Aftermarket Parts: These can be more affordable, but quality often varies, and issues may arise regarding compatibility. You can save money upfront, but weigh that against potential longevity and reliability issues.

Researching and Purchasing

When replacing parts, familiarize yourself with the exact specifications needed for your True cooler model. This ensures compatibility and proper function.

- Reputable Suppliers: Always choose trusted vendors to ensure you get high-quality parts that can withstand the rigors of daily use.

When to Call a Professional

While many inspections can be handled independently, some situations require expert intervention.

Complex Repairs

If an inspection reveals significant issues with components like the compressor, consider getting help from a professional. Repairing these sensitive parts demands expertise and specialized tools.

Persistent Problems

If you’ve been dealing with recurring issues, it’s time to consult with seasoned technicians. They can diagnose problems that might not be immediately clear.

Updating Technology

If you’re considering upgrades to your cooling systems, such as energy-efficient components, consultation with experts can guide you in the right direction.

Conclusion

Regular inspections are not just a routine task; they are a vital part of keeping your True cooler functioning smoothly and efficiently. You can prevent costly repairs, extend the lifespan of your unit, and maintain optimal performance by staying proactive about maintenance. By familiarizing yourself with your cooler’s components, setting a proper inspection schedule, and being attentive to signs of trouble, you ensure that your cooler remains a reliable asset in your business or home.

So, what are you waiting for? Make regular inspections a priority, and you’ll benefit from long-term savings and continued satisfaction with your equipment. Keeping your cooler in top shape is not just good practice; it’s smart business!